Automate your production planning, optimize your

processing, and save time.

Planning automatization

- We know – creating the production schedule is often a long and fallible task. That is why we have developed a planning automation platform that adapts and scales to the size of your team, regardless of industry

Instant results

- In a matter of weeks, we are able to implement advanced algorithms that will save you time in a variety of repetitive processes

Consultancy

- A thorough analysis of your business workflow and industry standards enables you to set specific, measurable goals that will help you take your production to the next level

Consultancy

A thorough analysis of your company and industry enables you to set specific, measurable goals that will help you take your production to the next level

Planning automatization

As creating the production schedule is often a long and fallible task, we created a planning automation platform that adapts and scales to the size of your team, regardless of industry

Workflow optimization

After critically examining your current workflows, we will collaborate to create new ones that will save you time in a variety of repetitive processes

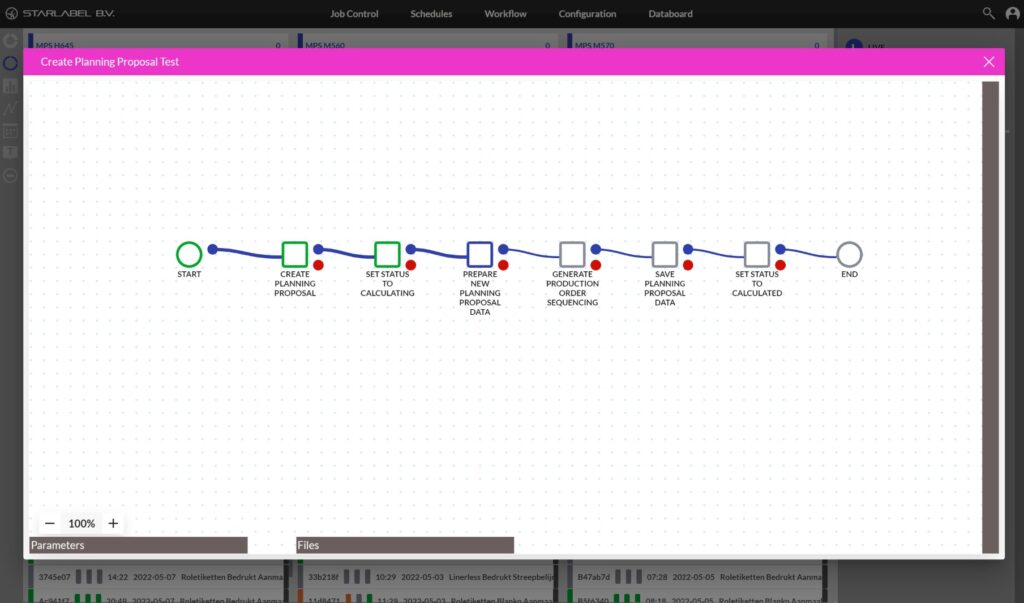

For automated planning, many details from the existing environment are loaded into the software so that the right variables, dependencies and calculations can be taken into account. With an intelligent software platform that automates as much as possible and reduces manual intervention to a minimum.

Typical optimizations and the data required for them, divided into so-called pillars. These pillars form the setup for implementation, integration and available optimization.

For automated planning, many details from the existing environment are loaded into the software so that the right variables, dependencies and calculations can be taken into account. With an intelligent software platform that automates as much as possible and reduces manual intervention to a minimum.

Typical optimizations and the data required for them, divided into so-called pillars. These pillars form the setup for implementation, integration and available optimization.

Data visualization that adapts to your specific configuration,

providing everyone with a unique overview

The software platform has a high level of intelligence built into it, along with linking options. This makes it possible to get up and running quickly using production data that is already digitally present in almost every production environment. Accordingly, the risks associated with lengthy software implementation procedures are avoided and the technology for automating production planning is truly within your reach.