We breathe labels

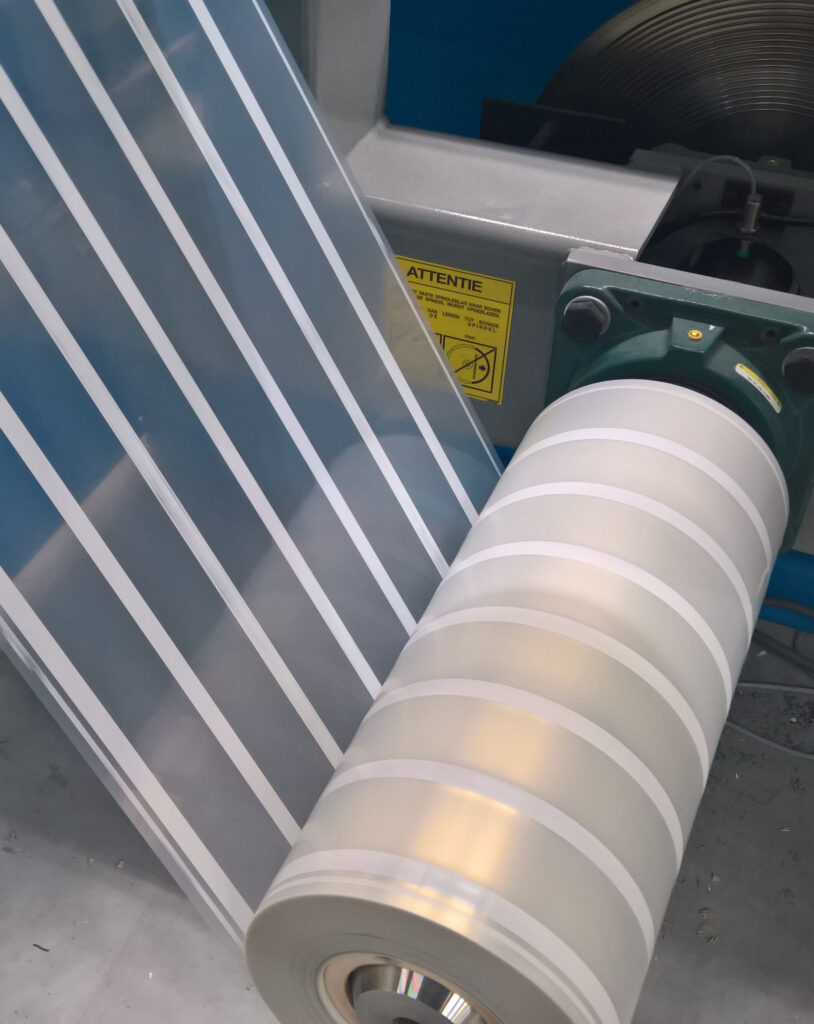

Our story begins in the 1980s with the founding of the label printing company Starlabel. Back then, label printers still coated their material themselves. But computers were already playing a role and our production planning was transparent with our own software in DBasic.

20 years later we have developed a low-code platform for ERP/MIS. Industries in production with special parameterization benefit enormously from the flexibility of the software. Widely used in the steel industry and of course in our own label and linerless printing shop.

But the meticulous planning of production jobs across all presses and departments was not fully automated and efficient. We have now developed the software platform for this. Automatic production planning: The most efficient production flow in your factory based on your parameters.

Blue Star Planning

team

Based in the

heart of Rotterdam

our team has developed a platform that improves planning and scheduling processes for production industries. If you enjoy planning, optimizing, and thinking out of the box, check out the positions we’re hiring for:

There are no open positions at the moment.

our team has developed a platform that improves planning and scheduling processes for production industries. If you enjoy planning, optimizing, and thinking out of the box, check out the positions we’re hiring for:

Here at Blue Star Planning, we’ve created a low-code platform that is all about optimizing large-scale factory production. The platform is developed in .Net and deployed in Microservices. Alongside specialized knowledge, the software engineer position requires affinity with math and algorithms as specialized algorithms are what provide production planning insights to our customers.

Backend Software Engineer responsibilities include:

- building APIs, database integration, and adding new features

- backend configuration and deployment

- developing clean, scalable, and high-performance code

- regular collaboration with our developer team

Required skills:

- medior/senior level of experience with .Net, Visual Studio, and C#

- good problem-solving skills: you love solving puzzles and have a user-centered approach

- you have a strong passion for coding

- degree in Computer Science (BA or Master)

What we offer to you:

- challenging and fun job in an international office

- organized SCRUM working environment (2-week sprints)

- our team structure leaves you plenty of space to pick your path of professional growth (eg technical consultancy)

- a structured approach to your growth (bi-yearly performance and salary reviews)

- team support on improving your coding skills, learning about new web technologies

- office in the city center (in other words: there are all possible commute connections and plenty of lunch options)

- competitive salary (estimated range of €3,500 – €4,500 per month) based on experience

How to apply:

1st step: send us the code you are most proud of! It can be something you’ll code especially for us, but it could also be a part of a code you have created for a different project.

2nd step: qualified candidates will be invited to join us for a conversation and a coding challenge in our office.

3rd step: if we believe you’d be a good fit for our team, we’ll make you an offer and hope to see you in the office soon!

If you would like to be a part of our core development team working on our low-code platform for production automation, send an email with your CV and the code you’re happy to share to ivan@bluestarplanning.com.

Here at Blue Star Planning, we’ve created a low-code platform that is all about optimizing large-scale factory production. The platform is developed in .Net and deployed in Microservices. We believe that with our specialism in creating Advanced Planning and Scheduling software, we can create the ideal production planning (sequence) to maximize the output of machines by reducing waste in time and materials. In this way, planning becomes the primary process, which we try to make the norm for all industries around the world to reduce waste in general.

As a full-time experienced Frontend Developer, you will fit into our team if you share an interest in developing a sophisticated ERP and MIS cloud platform solution that optimizes large-scale manufacturing processes. The skills that we are looking for are the following:

- Proficiency in TypeScript is a must

- Experience with React – or any other framework/library

- Fluency in English (our office is bilingual, but we mostly communicate in English)

- Object orientated programming experience

- Proactive and analytical approach to daily tasks

- RxJS is a bonus

What we offer to you:

- challenging and fun job in an international office

- organized SCRUM working environment (2-week sprints)

- our team structure leaves you plenty of space to pick your path of professional growth (eg technical consultancy)

- a structured approach to your growth (bi-yearly performance and salary reviews)

- team support on improving your coding skills, learning about new web technologies

- office in the city center (in other words: there are all possible commute connections and plenty of lunch options)

- competitive salary (estimated range of €3,500 – €4,500 per month) based on experience

How to apply:

1st step: send us the code you are most proud of! It can be something you’ll code especially for us, but it could also be a part of a code you have created for a different project.

2nd step: qualified candidates will be invited to join us for a conversation and a coding challenge in our office.

3rd step: if we believe you’d be a good fit for our team, we’ll make you an offer and hope to see you in the office soon!

If you would like to be a part of our core development team working on our low-code platform for production automation, send an email with your CV and the code you’re happy to share to ivan@bluestarplanning.com.

The low-code platform we’ve developed at Blue Star Planning focuses on increasing the efficiency of large-scale factory production. Our specialized algorithm provides production planning insights and suggestions to our customers, increasing their OEE (overall equipment effectiveness) and preserving production resources.

The low-code platform we’ve developed at Blue Star Planning focuses on increasing the efficiency of large-scale factory production. Our specialized algorithm provides production planning insights and suggestions to our customers, increasing their OEE (overall equipment effectiveness) and preserving production resources.

As an Econometrician, we expect you to be familiar with constrained-based planning, the traveling salesman problem, and benchmarks fitting in mass production. In this role, you will create algorithms to meet the demand of large-scale production.

What we offer to you:

- challenging and fun part-time role in an international office

- organized SCRUM working environment (2-week sprints)

- a structured approach to your growth (bi-yearly performance and salary reviews)

- team support on improving your technical skills

- office in the city center (in other words: there are all possible commute connections and plenty of lunch options)

- competitive salary based on your experience

How to apply:

If you would like to be a part of our core development team working on our low-code platform for production automation, send an email with your CV to ivan@bluestarplanning.com. I’d be happy to discuss the opportunities we have available.